Servo controlled denesting

The D-360 tray denester is a servo controlled denester with an available denesting surface of 300 x 600 mm. It is suitable for single or multiple denesting of trays with one or more compartments. The size of the tray or the required pitch on which the trays must be delivered to the packaging line determine the amount of trays that are denested per cycle.

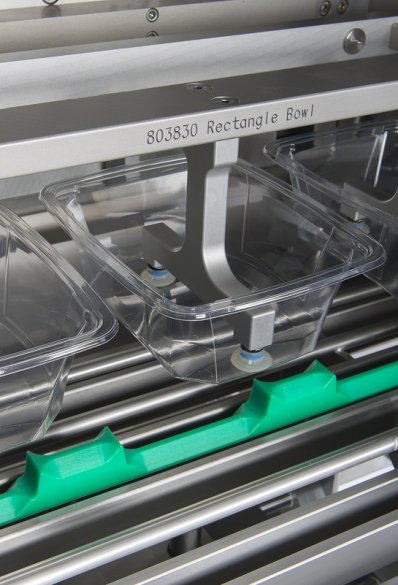

The tooling is very easy to exchange, which makes a very quick changeover between different tray sizes possible.

Features of the D-360

Quick changeover time

Denesting range

High speed

easily exchangeable tooling for quick changeover times

600 x 300 mm

20-30 cycles per minute/200-300 packs per minute (depending on the tray size)

Quick changeover time

easily exchangeable tooling for quick changeover times

Denesting range

600 x 300 mm

High speed

20-30 cycles per minute/200-300 packs per minute (depending on the tray size)

Specifications of the denester

- Smart servo-controlled denesting system

- Suitable for denesting trays, blisters and lids

- Single and multiple denesting of single and multi-compartment packaging

- Available as a stand-alone system or integrated into the line

- Denest at a fixed speed or on demand

- Application of product numbers to store specific product settings

- Easily exchangeable tooling for quick changeover times

This machine is widely used in these industries

Click outside of the modal to close it