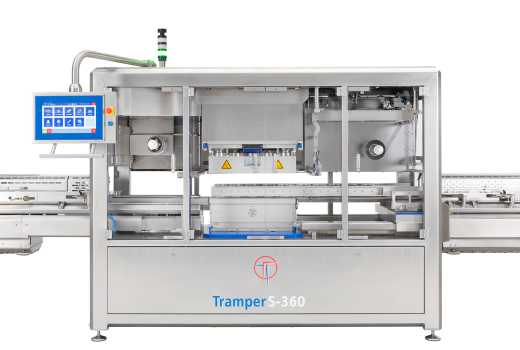

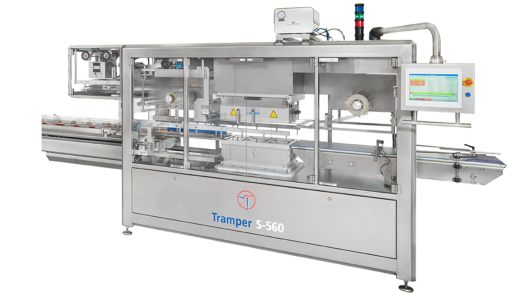

Tray sealers

Attractive product presentation, a longer shelf life and better protection during transport: the Tramper Technology tray sealer allows you to seal your product in any type of (sustainable) tray, tub or pot. The various models offer single or double lane packaging and are standardly prepared for MAP packaging. The precision in technology ensures optimal film usage and reduces waste to a minimum. High operational reliability, ease of use and safety make our tray sealing machines a flexible and trustworthy link in your production process!

Less energy, more output

All tray sealers are equipped with servo-controlled drives. Our sealing technique is unique. This technology creates benefits such as adjustable die closing speed, uniform seal quality, low consumption and a higher output.

Customization possible

We ensure that our tray sealers can be integrated seamlessly into a new or existing production environment, whether as a standalone unit or fully automated packaging line. Our tray sealers are fully in line with the industry requirements thanks to the right basic principles, continuous development and close contact with our customers. If our standard tray sealing machines are not suitable, we are happy to come up with a tailor-made solution.

Tramper Technology's tray sealers are available in five different standard models: